BEKOMAT i4.0 goes digital

22. September 2022

Networked compressed air preparation

BEKO TECHNOLOGIES is taking another step towards the fully networked compressed air preparation of the future. BEKOMAT i.4.0 is a fusion of proven condensate drainage and digitalisation. In addition to the reliable discharge of oily and contaminated condensate without loss of compressed air, the unit also communicates with control systems and control rooms. Thus, all industry expectations of intelligent systems such as networkability, remote monitoring and flexibility are fulfilled by the BEKOMAT i4.0.

PROVEN TECHNOLOGY NOW ALSO NETWORK-COMPATIBLE

BEKO TECHNOLOGIES offers a common industry standard with BEKOMAT. The robust unit drains condensate without pressure loss, thus saving energy and CO2 emissions. This is made possible by an integrated capacitive sensor, intelligent electronics for quantity-adapted condensate discharge and the pilot control of the solenoid valve. The new BEKOMAT i4.0 generation offers the user additional advantages in terms of digitalisation and increased process reliability. The IIOT-capable product range consists of 13 models for different performance levels and requirements and provides continuous real-time data on the status of each individual trap for optimum transparency and monitoring.

ADVANCED CONDENSATE MANAGEMENT

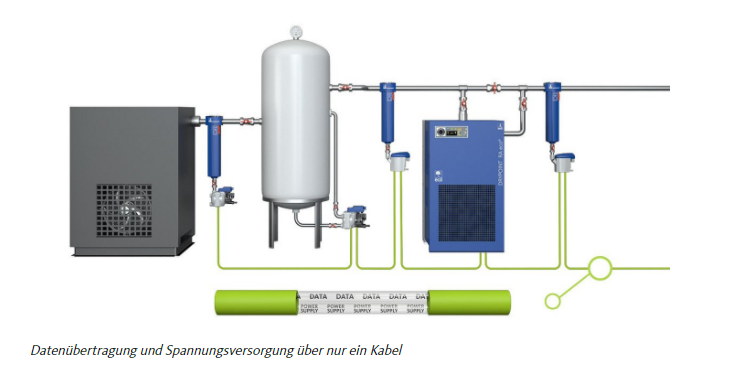

Central control centres receive the information from the BEKOMAT i4.0 condensate drain via an RS485 industrial bus interface. Intelligent condensate management is made possible by visualising the performance and function data of all connected steam traps in real time. Important conclusions about the entire compressed air system can thus be drawn from the status messages. In order to prevent failures and plan maintenance on schedule, early warning and alarm signals indicate targeted service measures.

One cable for power supply and at the same time for data transmission is sufficient for the new BEKOMAT i4.0 condensate drain. The daisy chain connection technology means that the cable is pulled from one unit to the next. This reduces the installation effort to a minimum and an extension of the system is possible without any problems.

NETWORKING WITH MINIMAL INSTALLATION EFFORT

YOUR ADVANTAGES

Digitisation as standard

- Connectivity and advanced communication

- Connection to RS485 interfaces in control rooms or suitable compressors and dryers

- Fully automatic operation and monitoring

Easy installation & low maintenance

- flexible connectivity

- Individual connection or daisy-chain topology with only one cable for data and power supply

Simple service

- Transmission of important details helps the service to act quickly and efficiently

No loss of compressed air during discharge

- low operating costs

High reliability

- Durable, dirt-resistant and robust

- No emulsion formation thanks to large valve cross-sections

- No failure-prone mechanical components

TO THE HISTORY

The BEKOMAT condensate drain has been built more than 5 million times to date. It was the first BEKO Technologies product to revolutionise the market, as for the first time it was able to drain condensate without loss of compressed air. This replaced solutions on the market at the time such as float traps or time-controlled solenoid valves which, in the event of malfunction, allowed valuable compressed air to escape unused into the environment. Thanks to the BEKOMAT, energy, costs and CO2 emissions can now be saved worldwide. The new BEKOMAT i4.0 series opens up whole new additional future opportunities through the advantages of digitalisation and process reliability can thus be increased even further.

Pdf-File DownloadWeitere News

It’s better to be safe than sorry!

22. September 2022

FILCOM Service. We ensure reliable operation of your compressor station!

Clean air for the highest demands!

22. September 2022

With the iFix technology from Filtration Group Industrial.

The new FILCOM online shop is here!

22. September 2022

Discover now!