Plastic in perfect form

22. September 2022

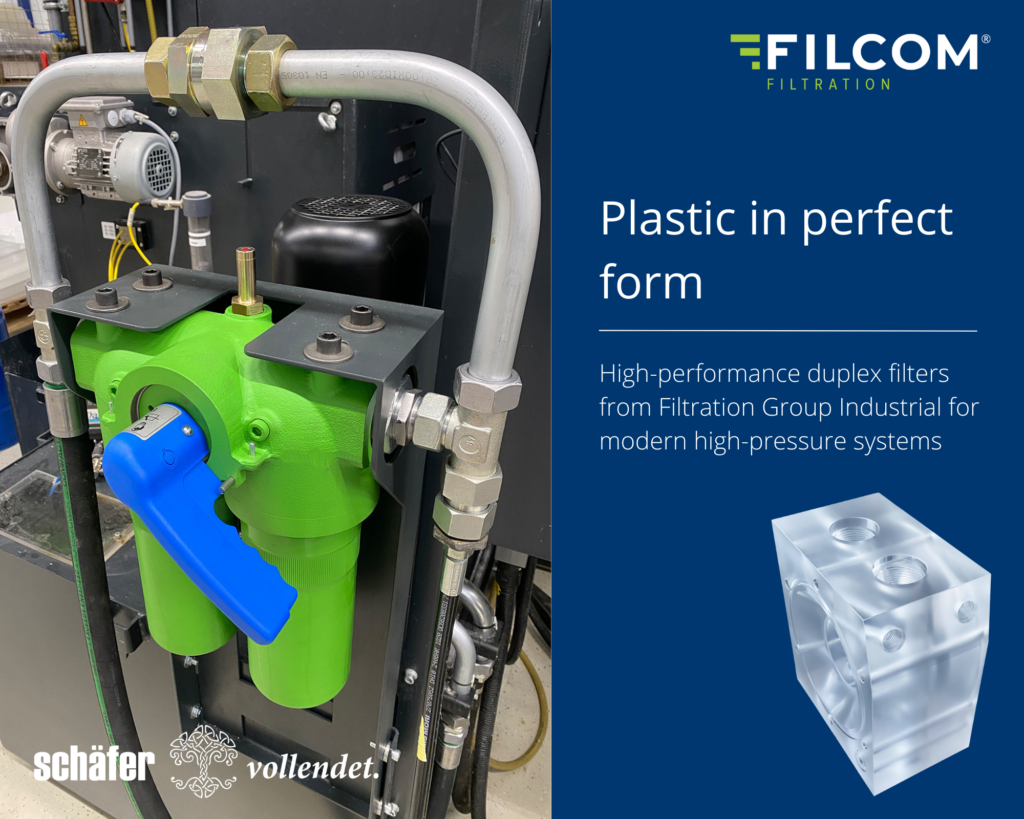

High-performance FG duplex filters for modern hydraulic systems

In metal and plastics processing, more than 90 percent of cooling lubricants are cleaned today, thus ensuring a smooth production process. Cooling lubricants minimize wear on expensive precision machines and make a decisive contribution to the surface quality of the manufactured products.

On a high-quality 5-axis milling machine, the Pi 370 duplex filter with a size of 300 l from Filtration Group Industrial takes over the filtration of cooling lubricant at our customer Schäfer Kunststofftechnik. The filter ensures reliable operation without downtime. Here, the duplex filter takes over the function of a safety filter (police filter). A pump draws in the cooling lubricant. The fluid runs back through the filter into the spindle via a hose. In these applications, the filter is connected downstream of the working filter. It has a safeguarding function and provides maximum safety for internally cooled tools, rotary pressure guides and fine machining bores. Especially when machining plastic parts with internal cooling of the tool, it is important that the cooling lubricant is free of minute particles, otherwise clogging can occur.

Top performance is achieved when experts meet at eye level and use their experience to develop solutions together. FILCOM GmbH also supports its customer Schäfer Kunststofftechnik GmbH for a further successful future in order to perfectly shape the interaction of products and experience. Because quality is the only thing that lasts in life – in order to continue to create plastic in perfect form in the future.

Weitere News

It’s better to be safe than sorry!

22. September 2022

FILCOM Service. We ensure reliable operation of your compressor station!

Clean air for the highest demands!

22. September 2022

With the iFix technology from Filtration Group Industrial.

The new FILCOM online shop is here!

22. September 2022

Discover now!