New definition of condensate separation

19. April 2023

QWIK-PURE – SAFE. CLEAN. MODULAR

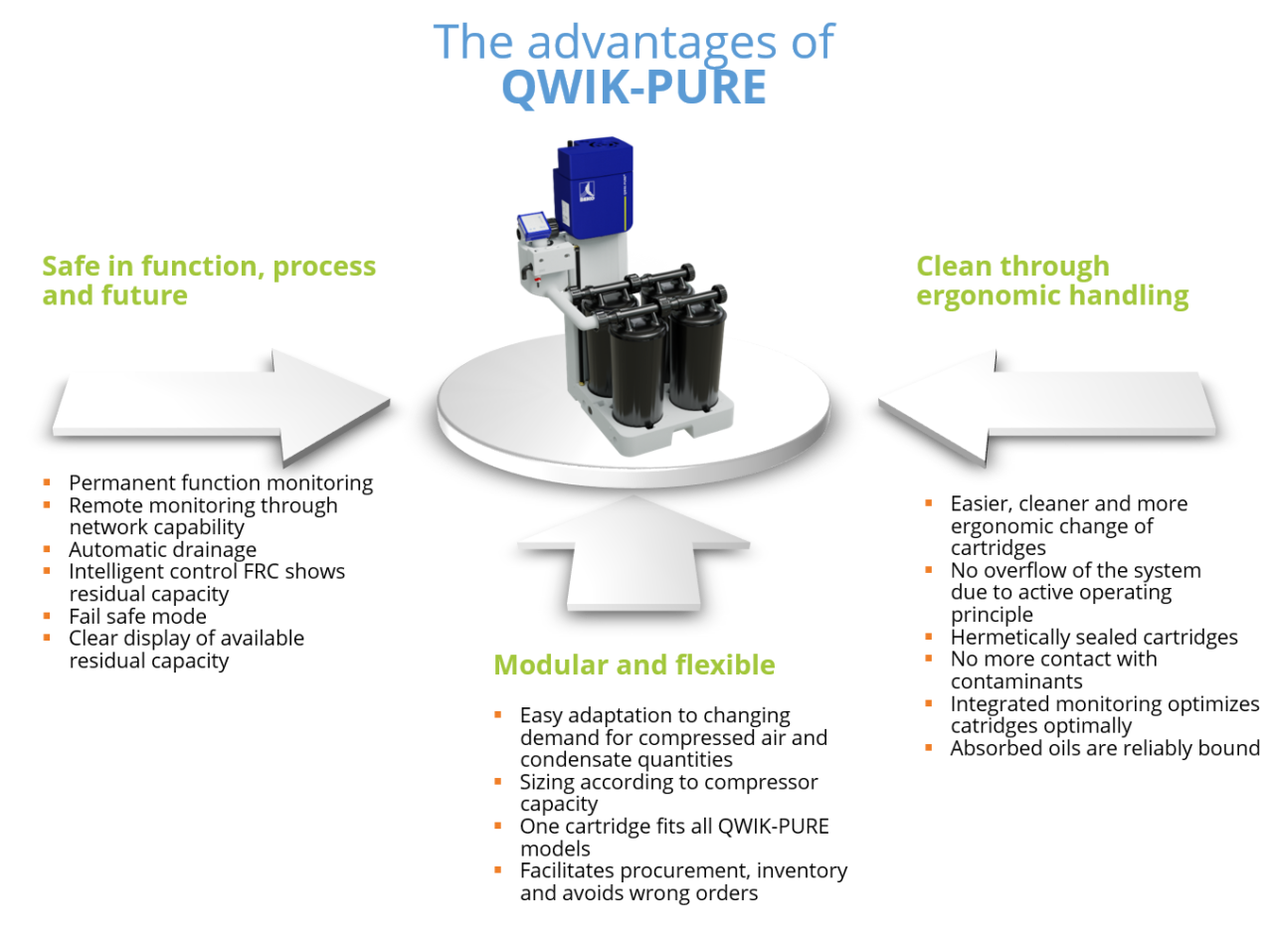

The world’s first active oil-water separator redefines and transforms condensate treatment. QWIK-PURE sets new standards with its active functions, fail-safe mode and modular design.

SAVING THROUGH ACTIVE SEPARATION

Active separation of condensate consumes compressed air and electricity. At the same time, the use of cartridges is more efficient and reliable, saving raw materials, energy and costs. Planned and fast service distribution and easy storage are further cost-saving factors that contribute to lower total cost of ownership (TCO). The absende of activated carbon and well-designed packaging protect the environment and also reduce the carbon footprint.

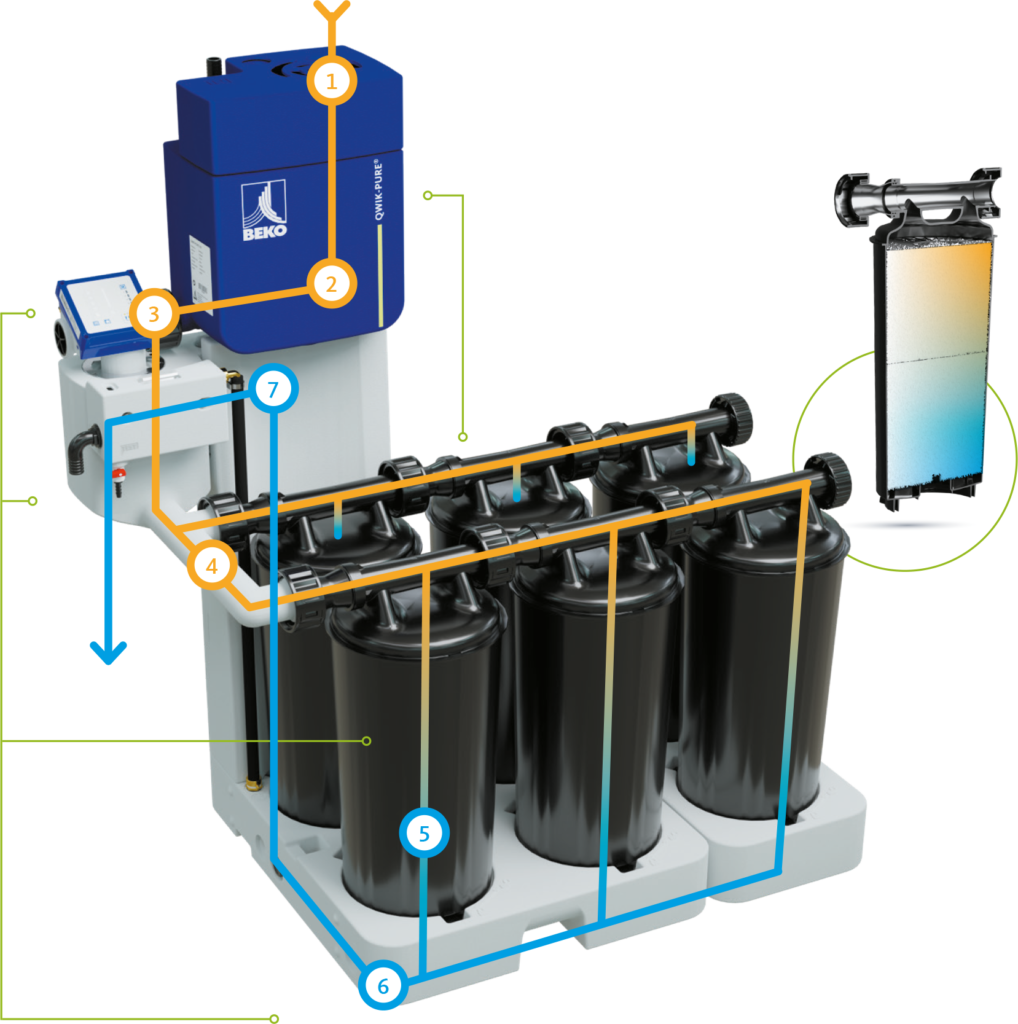

FUNCTION

While conventional oil-water separators work on the gravity principle and the condensate seeps into the filter media, in the QWIK-PURE the condensate is actively forced through the pre-filter and main filter by a light stream of compressed air. The cartridge is permanently filled with liquid to prevent it from drying and forming an impereable boundary layer. Problematic cultures with which employees or service personell could come into contact are hardly ever present.

The FRG integrated control system reliably displays the current remaining capacity of the cartridge, monitors the system and automatically regulates condensate separation. Even temporarily increased amounts of condensate can thus be safely disposed of. If problems arise, measures are initiated independently or an alarm is triggered. In the event of a malfunction or power failure, the QWIK-PURE continues to operate like a conventional gravity separator in fail-safe mode.

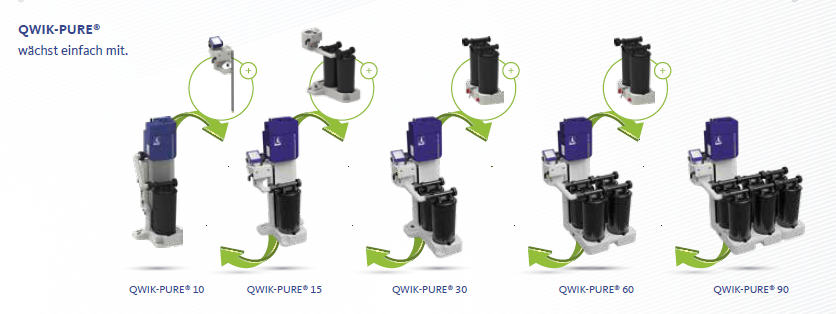

MODULES THAT GROW WITH THE CUSTOMER GUARANTEE FLEXBILITY

Adaptation to higher or lower demand in the blink of an eye. This creates decision-making security and additional safety reserves, while at the same time adapting service intervals and service work.

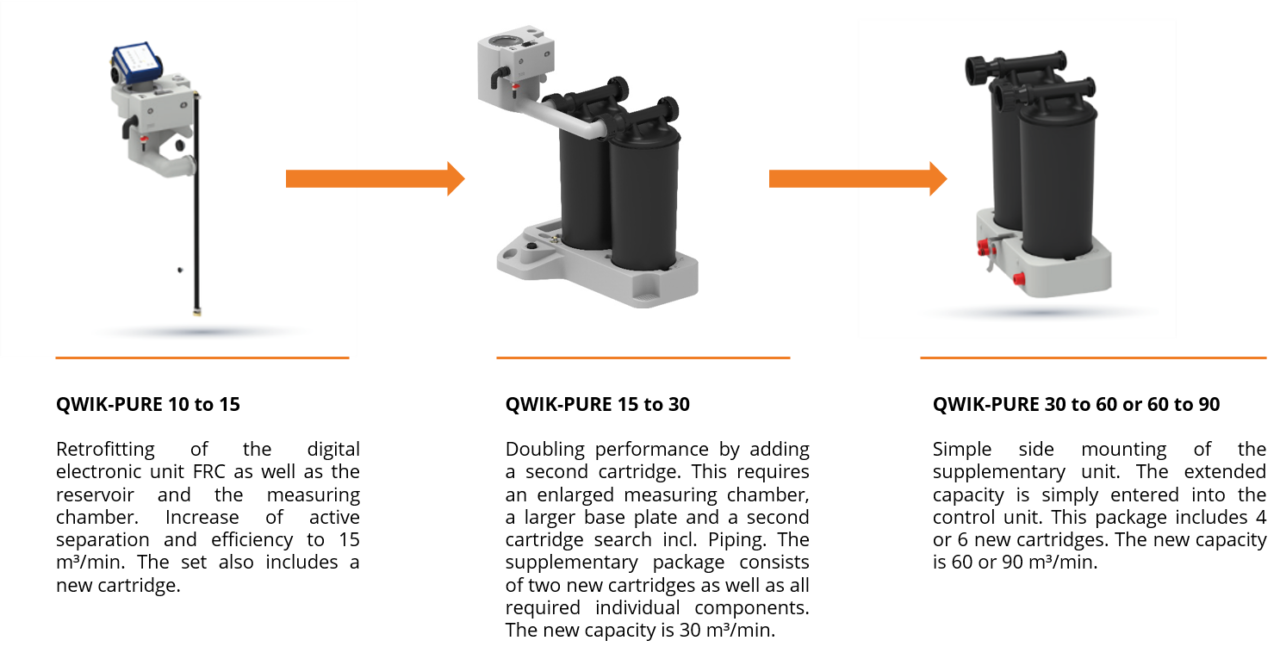

THE UPGRADE

ONE CARTRIDGE FOR ALL

We thus reduce procurement, warehousing and incorrect orders.

- Ergonomics in focus: for easy transport and assembly; the inlet tube serves as a non-slip and stable handle

- Hygiene-friendly cartridge change: an integrated valve in the base of the cartridges prevents liquids from escaping after the change.

- Cleanliness: the closed design prevents contact with absorbed substances inside the cartridge. Reliable binding in the pre-filter and main filter ensures that neither employees nor the treated and discharged condendsate are contaminated.

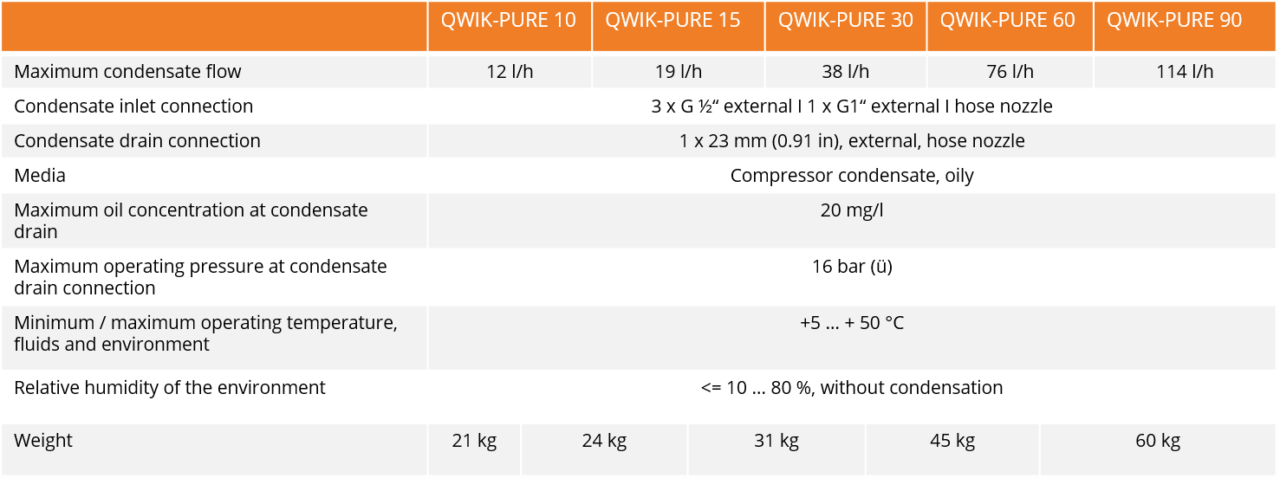

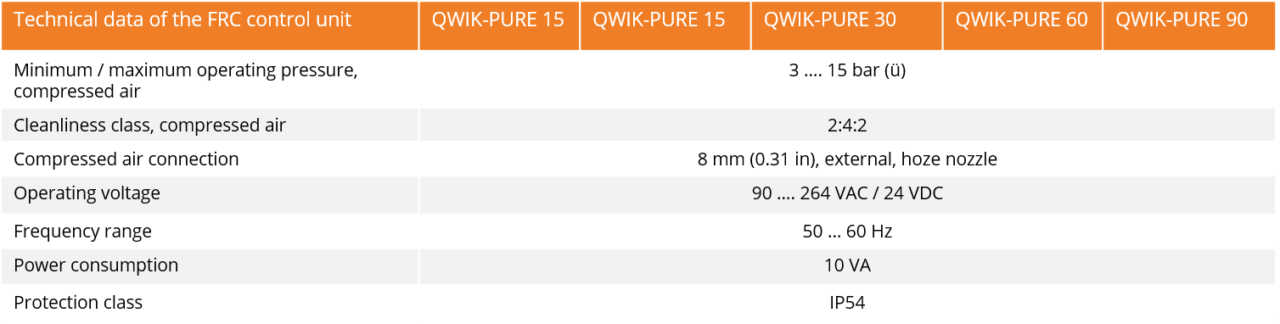

TECHNICAL DATA

INFO

As an expert for the entire compressed air treatment with decades of experience FILCOM GmbH together with BEKO Technologies is your contact in condensate technology. With the corresponding products such as the BEKOMAT condensate drains and the ÖWAMAT oil-water separator. For emulsified condensates we offer BEKOSPLIT, an efficient and worldwide proven condensate splitting unit.

FAQ

FREQUENTLY ASKED QUESTIONS ABOUT QWIK-PURE

Here you will find answers to your questions.

What are the consequences if the amount of condensate is greater than originally expected?

In such situations, the maintenance intervals are shortened slightly to ensure optimum functionality. However, there are clear limitations: In the event of an unexpectedly high volume of condensate, a smaller model such as the QWIK-PURE 15 could also be overwhelmed when a larger QWIK-PURE 90 is actually required.

Does the FRC really have intelligence or is it just a “simple” meter?

The FRC really shows intelligence and goes far beyond the function of a simple counter. On the one hand, it monitors the period until the next maintenance according to the specified intervals after one year. On the other hand, it can use various functions to analyze the service life of the filter and indicate when service is required.

How does the QWIK-PURE oil/water separator behave during a power failure?

In so-called fail-safe mode, the QWIK-PURE continues to function like a conventional gravity separator. In this mode, the increased water column between the inlet of the condensate and the cartridges results in a significantly improved separation of oil and water.

How does the system react when the power supply is restored?

The QWIK-PURE saves all relevant values during a power failure and continues to function seamlessly without loss of data or impairment of functionality as soon as the power supply is restored. Only the derivations in fail-safe mode during the power failure are not taken into account.

What does the W-LAN symbol mean?

The WLAN symbol indicates that the QWIK-PURE oil/water separator provides a local WLAN network for service purposes. This WLAN can be used to display key parameters and information that are relevant for maintenance and service work on the appliance. This WLAN function makes it easier for maintenance personnel to access relevant data in order to carry out efficient and precise maintenance.

What data is transmitted via the interface?

All relevant data, such as the number of switching cycles or the remaining capacity, is available via two different interfaces. This includes alarm notifications and other important information. The user can call up this information either via MODBUS RS485 or the WLAN interface. This makes it possible to quickly determine remotely whether maintenance is required in the foreseeable future.

Is it possible to connect the QWIK-PURE oil/water separator to a compressor control system or building management system?

Higher-level control systems can also be integrated using the standardized interface. However, due to the variety of different systems, it must be checked in each individual case which connections are possible.

How is the inflowing condensate handled during maintenance?

During maintenance of the QWIK-PURE oil/water separator, the accumulated condensate is stored in the pressure relief chamber. After replacing the cartridges, the condensate is treated directly.

Is it necessary to carry out pre-washing?

No, the new cartridges of the QWIK-PURE oil-water separator no longer need to be pre-watered. They work efficiently without pre-watering.

How do I dispose of the used cartridges?

We recommend closing the used cartridges with the enclosed plugs and disposing of them in accordance with local regulations for oily waste. A disposal key is provided in the operating instructions.

What is the energy consumption of the QWIK-PURE?

The energy consumption of the QWIK-PURE varies depending on various factors. In regular operation, during a draining process, the compressed air consumption of the device is only 3 to 7 liters per draining process. During servicing, the compressed air consumption is between 15 and 70 liters.

In terms of power consumption, this is so low that it is negligible and is therefore not specifically stated. Power consumption is mainly limited to supplying the LEDs used to display important information. Overall, the QWIK-PURE is characterized by its efficient use of energy.

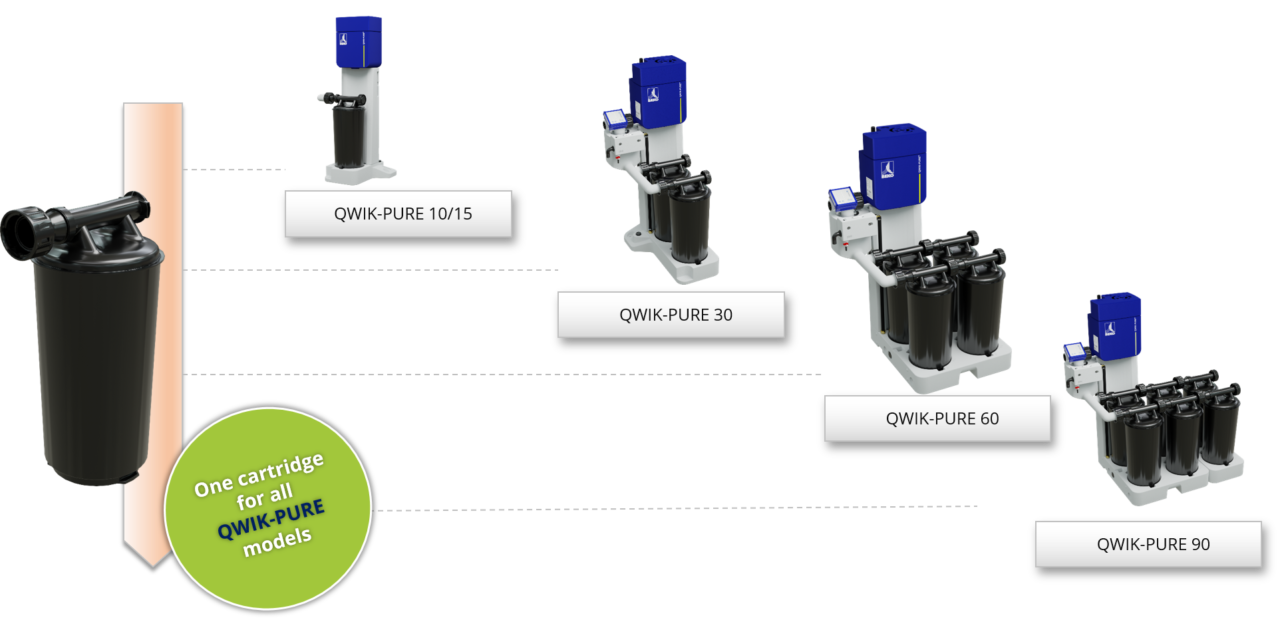

What materials is the cartridge made of?

The cartridge of the QWIK-PURE is made of a polypropylene material specially optimized for condensate separation. The wall thickness of the cartridges is thin in cross-section, which means that only a small amount of plastic is used. In addition, the use of mineral and textile materials and activated carbon has been avoided, as these are less sustainable in terms of disposal and carbon footprint than the optimized polypropylene material. The packaging in particular is designed to be sustainable and only around 10% of the material that is normally disposed of is plastic.

What are the environmentally friendly features and benefits of the QWIK-PURE?

The QWIK-PURE is characterized by an extremely reliable and safe operating principle that ensures efficient removal of oil from the condensate, preventing unwanted discharge into the waste water. This reliability has led to a significant reduction in maintenance visits and potential breakdowns. Due to its efficient design and the use of polypropylene material optimized for condensate separation in the cartridges, the QWIK-PURE minimizes potential breakdowns or problems. This results in fewer service calls and associated trips, which is not only cost-effective but also has a positive environmental impact by reducing energy consumption and CO2 emissions.

The packaging is virtually plastic-free and space-saving on Euro pallets, which can significantly reduce the usual waste, especially during maintenance.

What is the reason for not using recycled plastic?

At present, no recycled plastic is used in the cartridges of the QWIK-PURE. There are several reasons for this. Firstly, recycled plastic is considerably more expensive than conventional plastic, which would lead to higher production costs and a potential increase in the final price of the product.

Another important factor is ensuring the quality and reliability of the product. Cartridges made from recycled plastic could potentially have irregularities such as inclusions or other defects that could lead to leaks or malfunctions. As the functionality and safety of the QWIK-PURE are of the highest priority, the use of recycled plastic is avoided to ensure that the cartridges are reliable and leak-proof.

Nevertheless, the QWIK-PURE continues to use sustainable materials such as our optimized polypropylene material to reduce the amount of plastic and make a positive contribution to the environment. This careful selection of materials makes the QWIK-PURE environmentally friendly without compromising on quality and performance.

What are the reasons for not recycling the cartridges?

The decision not to reuse the QWIK-PURE cartridges is based on the objective of safety and protection of people and the environment. The cartridges contain contaminated components that are safely bound in the cartridge. Sealing and single use of the cartridges ensures that there is no possibility of people coming into contact with the contaminated substances during the maintenance process or after emptying.

The reuse of cartridges could potentially pose a risk of releasing harmful substances, especially if reprocessing is not carried out correctly. Leaks could also occur. We have therefore deliberately decided against opening and refilling cartridges to ensure the safety of our customers and maintenance technicians. The use of disposable cartridges also ensures that the disposal process can be carried out in a simple and controlled manner, minimizing potential risks to the environment and human health.

What procedures are prescribed for the disposal of used cartridges?

The regulations for oily waste apply to the disposal of used cartridges of the QWIK-PURE oil-water separator. In accordance with local regulations and laws for oily waste, the used cartridges should be sealed with the plugs provided to prevent condensate or oil from escaping. They should then be disposed of properly as oily waste. Further information on disposal and the corresponding disposal key can be found in the operating instructions.

Doesn’t the use of QWIK-PURE lead to an increased amount of waste?

No, the use of the QWIK-PURE oil/water separator does not lead to an increase in the amount of waste. In fact, the amount of plastic used in the cartridges remains unchanged compared to previous versions.

By reducing the amount of plastic in the packaging, fewer resources are consumed and less plastic waste is generated. This contributes to an improved environmental footprint of the product. The innovative functionality ensures that the cartridges are fully loaded and therefore utilize the entire capacity. This enables a longer service life for the cartridges.

Does the use of QWIK-PURE increase disposal costs?

The regulations on waste disposal vary from country to country and concern both the limit values for condensate treatment and the disposal of used cartridges. In Italy, for example, billing is based on weight. Thanks to automatic dewatering before disposal, our cartridges are now significantly lighter than before, making them more cost-effective than alternatives.

How is free oil handled?

The QWIK-PURE oil-water separator ensures reliable binding of free oil in the cartridge. This innovative technology eliminates the need for separate drainage and disposal. This means that the collected oil is safely retained in the cartridge and does not end up in the environment. The special design of the cartridges ensures effective retention and safe storage of the oil, enabling controlled disposal.

Weitere News

It’s better to be safe than sorry!

19. April 2023

FILCOM Service. We ensure reliable operation of your compressor station!

Clean air for the highest demands!

19. April 2023

With the iFix technology from Filtration Group Industrial.

The new FILCOM online shop is here!

19. April 2023

Discover now!